Tesla aluminum PDR specialists offer a cutting-edge, paintless damage repair solution for Tesla vehicles' unique aluminum frames. Utilizing precision instruments, they reshape metal without cutting or welding, preserving original finishes and structural integrity. This eco-friendly method minimizes waste, eliminates repainting, and is suitable for various damage types, ensuring vehicles look as good as new while offering faster, more cost-effective repairs compared to conventional auto painting services.

“Discover the future of damage repair with Tesla’s innovative Aluminum PDR (Paint-Free Damage Repair) system. This cutting-edge approach revolutionizes car maintenance, offering a paintless solution for dings, dents, and scratches. In this comprehensive guide, we explore Tesla’s unique aluminum expertise and the vital role played by specialists in the process. Learn how their skills transform damaged vehicles, preserving their pristine finish and enhancing overall vehicle value. Embrace the power of aluminum PDR with our expert insights.”

- Understanding Tesla Aluminum PDR: A Comprehensive Guide

- Benefits of Aluminum for Paintless Damage Repair

- The Role of a Specialist in Tesla's PDR Process

Understanding Tesla Aluminum PDR: A Comprehensive Guide

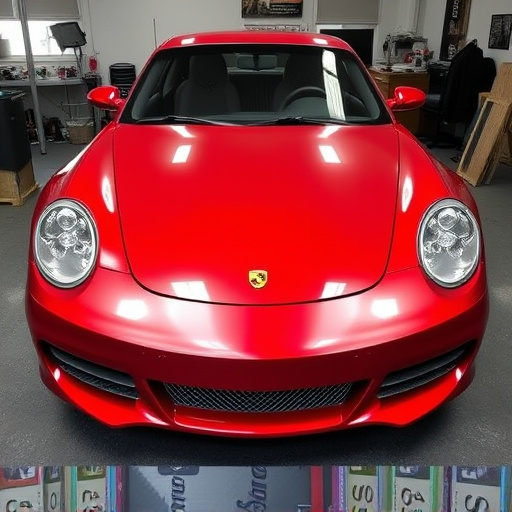

Tesla Aluminum PDR Specialist offers a revolutionary approach to car damage repair, particularly focusing on Tesla vehicles’ unique aluminum frames. This specialized technique, known as Plastic Deformation Repair (PDR), is a paint-free method that not only restores damaged areas but also maintains the vehicle’s original finish and structural integrity. By employing advanced tools and techniques, these specialists can effectively handle various types of car damage, from minor dents to more complex deformations.

Unlike traditional collision repair methods, Tesla Aluminum PDR Specialist leverages precision instruments to reshape metal without cutting or welding, preserving the vehicle’s aesthetic value. This meticulous process involves heating and manipulating the aluminum to return it to its original form, ensuring a seamless fit and finish. Whether repairing a Mercedes-Benz collision or addressing smaller incidents, these professionals ensure that your Tesla remains as good as new while promoting eco-friendly practices by minimizing waste and eliminating the need for repainting.

Benefits of Aluminum for Paintless Damage Repair

Aluminum has emerged as a game-changer in the world of paintless damage repair (PDR), especially for Tesla vehicles. Its unique properties make it an ideal choice for professionals specializing in car damage repair and vehicle collision repair. One of the key benefits is its superior ductility, allowing technicians to gently work around intricate designs and curves without causing additional stress or damage to the original surface. This precision is particularly valuable in classic car restoration projects where preserving the vehicle’s historical integrity is paramount.

Furthermore, aluminum offers excellent corrosion resistance, ensuring that the repaired areas remain free from rust and oxidation, even after exposure to harsh environmental conditions. Its lightweight nature also translates into faster drying times for repair compounds, reducing the overall labor cost and time spent on repairs. With these advantages, Tesla aluminum PDR specialists can efficiently tackle a range of issues, from minor dents and scratches to more complex car damage repair scenarios, keeping vehicles looking their best without the need for traditional paint applications.

The Role of a Specialist in Tesla's PDR Process

A Tesla aluminum PDR specialist plays a pivotal role in the company’s innovative damage repair process, offering an advanced and paint-free solution for auto repairs. PDR (Paintless Dent Repair) is a cutting-edge technique that focuses on removing dents and dings from vehicle bodies without the need for traditional auto painting or extensive auto maintenance. These specialists are trained to utilize specialized tools and equipment to gently work around the dent, returning the metal to its original form and smoothness.

By employing PDR methods, Tesla owners can benefit from faster and more cost-effective dent removal compared to conventional auto painting services. The specialist’s expertise lies in identifying suitable cases for PDR, understanding the unique properties of aluminum materials, and applying the right techniques to ensure a perfect repair that matches the vehicle’s original finish, enhancing both aesthetics and value. This specialized approach is particularly advantageous for minor incidents like door dings, fender benders, or parking lot scratches, providing an efficient solution without the time and costs associated with conventional auto painting procedures.

Tesla aluminum PDR specialists play a pivotal role in ensuring efficient and effective paint-free damage repair for Tesla vehicles. By leveraging their expertise and specialized techniques, these professionals offer significant benefits such as minimal disruption to the vehicle’s finish, cost-effectiveness, and rapid turnaround times. Understanding both the unique properties of aluminum and the precise steps involved in the PDR process is key to achieving optimal results. Thus, when it comes to Tesla aluminum PDR, relying on a specialist ensures your vehicle receives the best possible care.